3 Material Innovations that Make Metal Buildings Worth the Investment:

How Construction Technology Solutions Ensure Long Life for Metal Buildings

Owners of commercial and industrial businesses across all industries rely on the efficiency of pre-engineered metal buildings (PEMBs) to help reduce their total cost of ownership.

PEMB construction is a popular choice for aviation or aerospace facilities, warehouses, manufacturing plants, and agricultural operations. They are also effective for commercial use like retail or restaurants, churches, institutional buildings, and self-storage units.

Metal buildings inherently come with several advantages over traditional construction materials--but what exactly makes PEMBs worth the investment?

It boils down to the individual components.

Hard at work are several innovative materials that make up the sum of a metal building, which together affect its energy efficiency, durability, appearance, and maintenance.

In this post we'll take a glance at three innovative components of PEMB design that make metal buildings worth the investment: Paint, Aesthetics, and Roofing.

Know Your Building

Whether you're an owner of a metal building or are considering building one for your business, you might be curious to know how your investment breaks down into measurable elements.

"It's important to appreciate the innovative components and performance of a metal building," says Ken Thomson, founder of Facility Builders & Erectors.

"Most people I talk to these days don't get into the details of metal buildings or the performance of specific components, and I think it's important to know those details, so that you have a clear understanding of the items making a difference to your total cost of ownership."

3 Material Innovations in Metal Building Design:

1. Paint: Durability and Energy Efficiency

When it comes to pre-engineered metal, paint is about much more than just color.

To extend the life of a building, a durable resin-based paint system was invented in 1965 especially for steel panels: The Kynar 500® PVDF coating system.

The Butler-Cote™ finish system incorporates the Kynar 500® and the Solvay Hylar 5000® PVDF technologies across Butler's® pre-engineered metal wall and roof systems.

"There's a reason these finishes are nicknamed '40-year finishes,' Thomson says, "You put it on, and you're done with it for 40 years. It's a high-performance finish."

PVDF finishes resist chipping, fading, cracking, mold, and mildew in any weather conditions, and retain color and gloss for decades.

Trusted on everything from monuments and skyscrapers to residential homes, it's another reason to consider using pre-engineered metal panels as a part of the architectural solution of a building.

Besides durability, there are coatings designed for heat abatement especially useful in warmer zones; the reflective material in the finish can reduce solar heat by several degrees.

"This coating technology has been around for several years, but I think not many people know about it as a valuable option for their metal building," says Thomson.

2. Aesthetics: Diversity of Appearance

"Technology has allowed us to design diverse and visually interesting metal buildings," says Thomson. "Different wall systems, different shapes, different finishes, different styles...they all speak to the ability of technology to deliver unique and aesthetically pleasing products that are also going to perform well for many years."

Advances in pre-engineered metal wall systems, for example, give an owner the option to create an architecturally dynamic building. Beyond the classic high-performance Butlerib® wall systems, Butler's Thermawall™ systems come in fluted, fineline or flat style panels to create a uniform attractive appearance, while also saving costs by giving the interior metal panel a finished look without the need for additional materials.

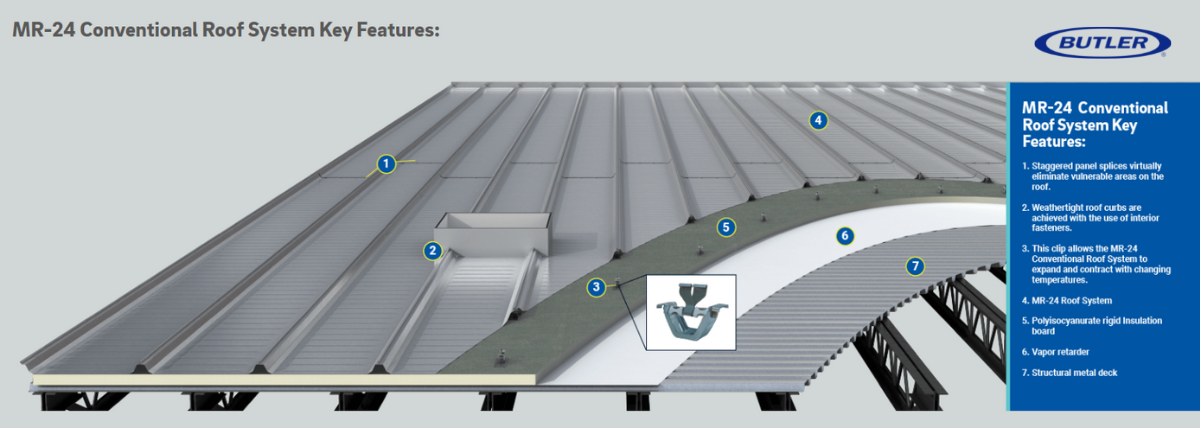

3. Roofing: Designed to Move

Most people don't think of a roof as something that moves.

But in the case of Butler's MR-24® standing seam roof system, that is exactly what it is designed to do!

"With hot and cold temperatures there's naturally expansion and contraction," says Thomson. The Butler standing seam roof is designed to move several inches--depending on the size of the building--to allow for that naturally occurring experience.

"It's a very simple, very well-thought-out solution," adds Thomson, "to ensure that the roof--which protects everything inside--is performing the way that it should and is not going to become fatigued over time because of its inability to move or expand and contract with the environment."

Because the roof system is specifically designed with movable clips to accommodate roof movement under changing temperatures, it can save up to 90% on roof maintenance costs.

"There are MR-24® standing seam roofs out there over 40 years old that show no signs of having to be redone--and probably have another 20 or 30 years of life in them," says Thomson.

For added energy savings, the roof panels also come in a choice of several "cool" colors that offset the sun's heat.

Innovative Materials Make Metal Buildings Worth the Investment

With robust materials and finishes designed to protect your investment, pre-engineered metal building systems are a popular way to go when the objective is to build a durable, attractive, energy-efficient and low maintenance building featuring construction technology solutions that promote a building's long life of service.

The Total Cost of Ownership

The total cost of ownership is the key factor in considering your preferred method and materials of construction. As your pre-engineered metal building contractor, Facility Builders and Erectors will, as part of the metal building shell solution, also factor in insulation systems, daylighting systems, doors and windows, equipment support platforms and other accessories to arrive at a complete building solution that will provide the highest return on investment for your facility project.

Call us today for a consultation, and to learn more about the benefits of building with the innovative, durable, energy-efficient components of pre-engineered metal building systems.

Published on June 21, 2022